PCB manufacturing and assembly

Complete HMI Solutions – From PCBs to Final Assembly

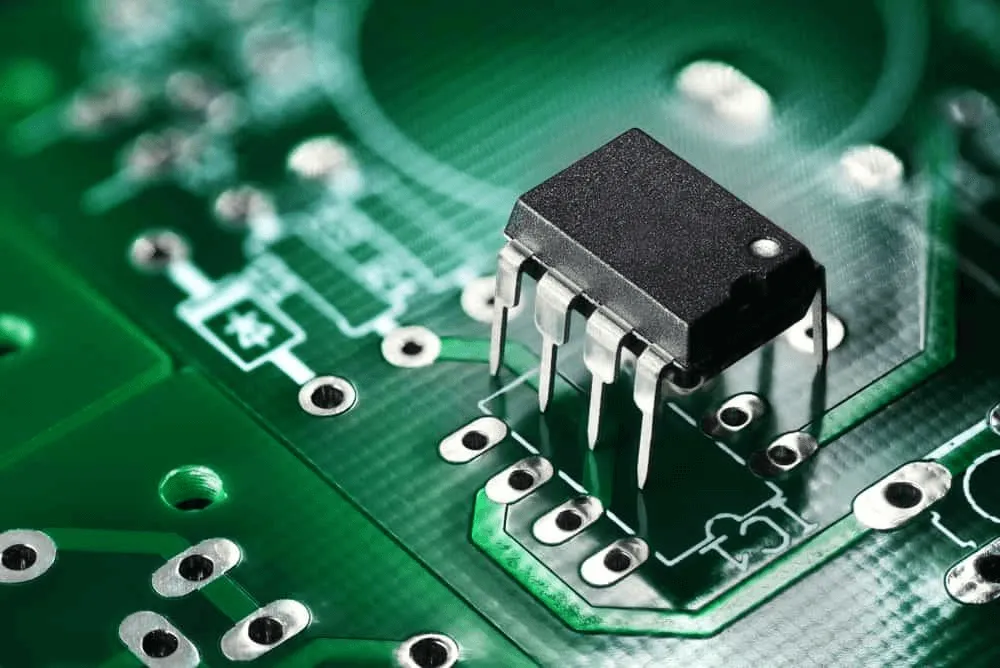

In addition to developing and manufacturing molded parts and input keypads for HMI devices, we also supply printed circuit boards (PCBs) and provide EMS (Electronic Manufacturing Services) to offer you a complete solution for fully integrated operator interfaces.

Flexible PCBs – ideal for space-saving and dynamic applications

Rigid and rigid-flex PCBs – robust yet adaptable for demanding systems

Single-sided, double-sided, and multilayer PCBs – from simple to highly complex circuit designs

Assembly is carried out with precision and in line with your specifications, ensuring every PCB is perfectly suited to its intended application.

Polyester Switching Foils – A Cost-Effective Alternative

For budget-sensitive projects, we offer double-sided polyester circuit foils as an alternative to rigid or flexible PCBs. These circuits are reliable and highly economical.

Manufacturing – circuit layouts are applied to both sides of the foil via screen printing

Through-hole plating – layers are connected using conductive paste

Protection – carbon paste overlays protect silver conductor tracks from migration

Our comprehensive EMS services support you from development through to mass production. Whether it’s membrane keyboards, silicone keymats, or touch displays – we combine all components into a single, custom-built control device tailored to your exact needs.

Silicone Keymats with Matching Circuit Boards – Precise and Durable Switching

We supply both silicone keymats and the corresponding circuit boards, ensuring a direct and reliable switching function. The keymat sits directly on the underlying PCB, providing precise actuation and long-term durability.

For applications demanding the highest reliability, we recommend gold-plated contact surfaces for stable conductivity and extended service life. As a cost-effective and highly chemical-resistant alternative, screen-printed carbon is also frequently used.

To ensure optimal functionality, the PCB contact area should be at least 0.5 mm larger in all directions than the contact area of the key. For specialized applications—such as rocker switches or keys with metal domes—please share your PCB contact layout with us so we can develop the ideal solution for your needs.

Contact us to learn more about our customized switching solutions. We will gladly support you in designing tailored combinations of keymats and circuit boards.

Hot Melt Molding Process

Also known as low-pressure injection molding, the hot melt molding process provides reliable protection for sensitive electronic components such as circuit boards, sensors, and more against harmful environmental effects. Its gentle handling of materials makes it ideal for delicate components that require a durable and resilient protective coating.

During the process, components are placed into a custom mold, then molten plastic flows around and evenly encapsulates them. By selecting from a range of materials, specific requirements can be met to enhance flexibility, impact resistance, and shock absorption, while also improving moisture resistance and sealing. This results in components that are well-protected against water, dust, and other external influences.

Furthermore, materials can be tailored to offer high resistance to UV radiation and chemicals, making hot melt molding especially suitable for demanding industrial or outdoor applications. The plastic color can also be customized to satisfy both aesthetic and functional needs.

Overall, hot melt molding is a versatile and effective method to provide long-lasting protection against corrosion, environmental exposure, and mechanical stress—offering a robust solution for use in challenging environments with high humidity or extreme temperature changes.

Advantages of the hot melt molding process

1. Protection against moisture, corrosion, chemicals, UV radiation and mechanical stress

2. Diverse materials: Meet requirements for flexibility, impact resistance, shock absorption, tightness and color.

3. Application possibilities:Integration of holes, screw threads or direct use as a housing.

Technical details:

Injection pressure: 1,5 to 40 bar

Temperature range: -50° to +200°C

References

Steron Solutions LLP

Solutions That Stand

Maharashtra, India

+91 8208123334

info@steronsolutions.in

Extra Links

Privacy Policy

Website-Disclaimer

Terms and Conditions